Purchasing used CNC machines can save you a lot of money. But beware, not all dealers are created equal. It is important to pay attention to the number of hours a machine has logged and whether it is upgradable. You want a machine that can scale up against high demand within a reasonable timeframe.

Whether you're an experienced machinist, a startup or existing business, used CNC machines can provide you with the tools you need to streamline production, increase efficiency and boost profits. But there are some things you need to know before purchasing any machine. These machines use a computer program, written in the international standard language G-code, stored on the machine’s memory and executed by the microcomputer that controls the tool’s operations. Each axis of the CNC has its own program, which determines the movement and functions of that axis.

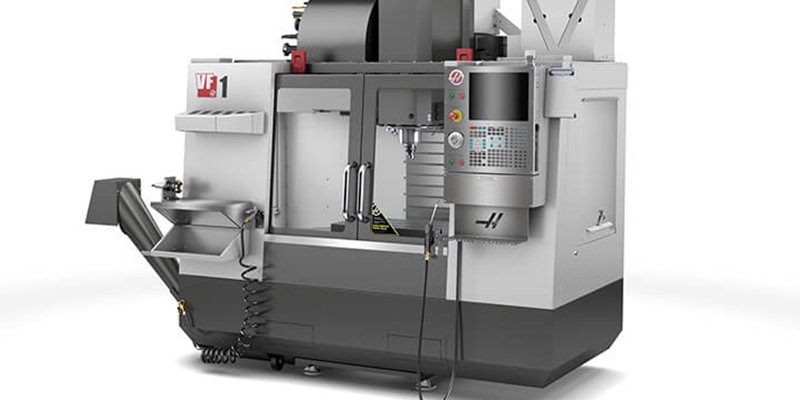

Known for their economical construction and simple-to-learn controls, Haas CNC mills are ideal for small shops and hobbyists. The company has an extensive line of vertical machining centers (VMCs), horizontal machining centers and CNC lathes. A downside to these machines is limited spare parts availability in the United States. Buying from an established dealer, such as Napoleon Machine, ensures you'll receive the proper parts and service. You also get a proven track record of performance.

CNC machines can be used for cutting, milling, drilling, engraving, marking, etching, cleaning, and welding. They are also used for bending, turning, and grooving. They can be purchased in new or used condition. The choice depends on the needs of a particular company. New machines are usually more expensive, but they offer a warranty and installation services. Used machines can be cheaper but are more likely to have hidden defects or malfunctions. They may also require more maintenance and inspection costs. It is important to consider the size and specifications of the machine to ensure it meets production requirements.

Depending on the type of machine you need, there are several different manufacturers to choose from. The most popular include SNK, Okuma, and Toyoda. These manufacturers are known for their quality and advanced technology. Their machines are often used in various industries, including automotive, aerospace, and medical. CNC machines make high-quality parts, and they can be programmed to do many jobs in a single operation. In addition, they are efficient and use less energy than other manufacturing methods. This reduces operating expenses, and it also helps to decrease the risk of human error. Those that need to used cnc equipment for sale they will visit here.

The cost of a CNC machine depends on its size, power, and cutting speed. It can also be affected by the brand and reputation of its manufacturer and optional features. Some machines can work with a wide variety of materials, and these are generally more expensive than those that only handle one type of material. Other factors to consider when choosing a used CNC machine include service and support, programming and software, working area size, and more. Contact our experts with details about your application to find a suitable used CNC machine. Our experts are available to answer your questions at any time. Start your research today. You’ll be glad you did.

Used CNC machinery is often more cost-effective than new equipment. It allows companies to scale up in a short amount of time and avoid costly startup costs, while also minimizing risk. This is especially beneficial when the market turns down and requires them to cut their losses and reduce production. When buying a used EDM machine, you should look for a dealer that offers tech support and setup. There are many problems that first-time CNC users encounter, and you’ll want a dealer who knows how to help you through them.